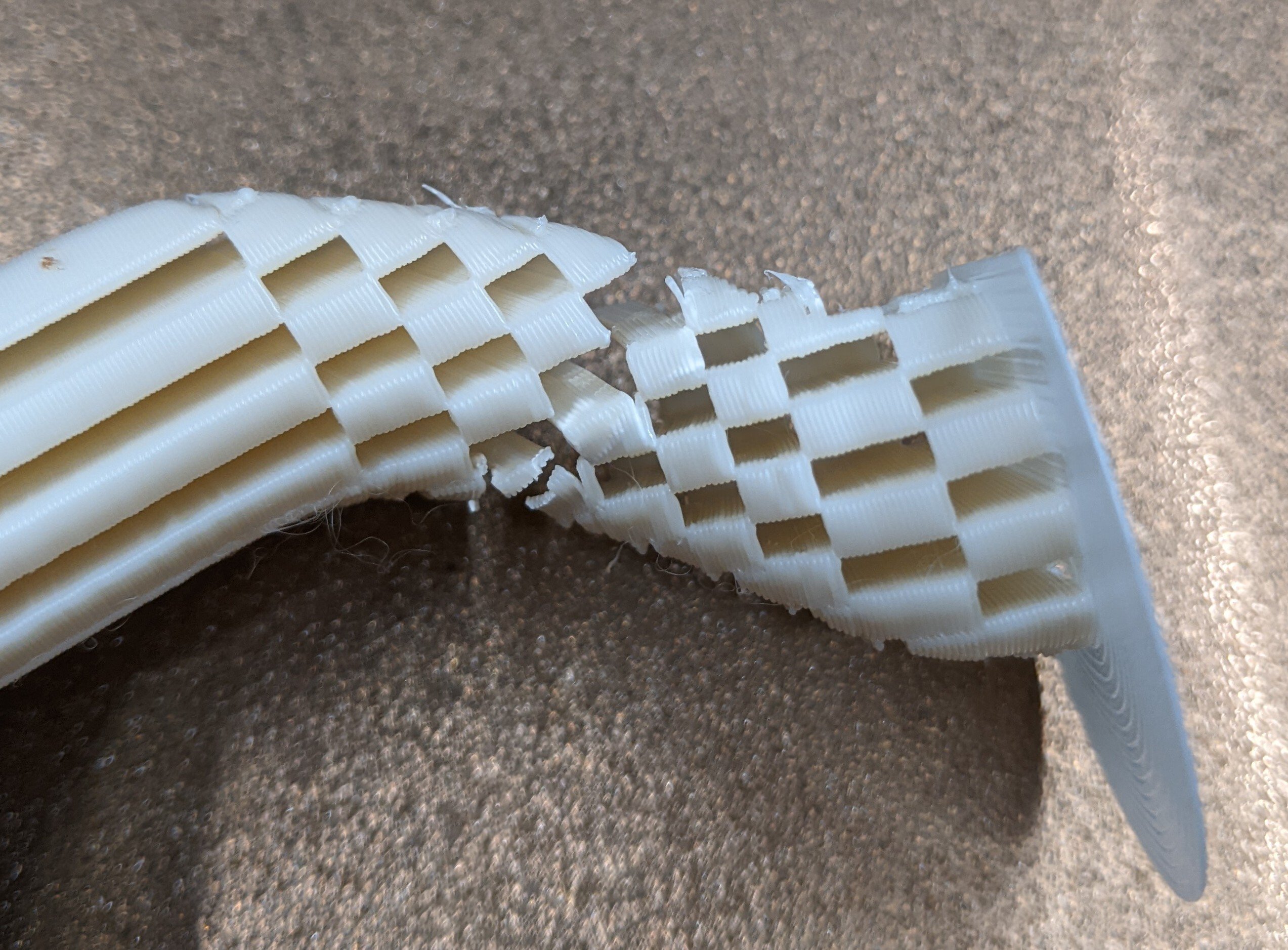

At least so far. The first go round had the nozzle crash into the tree support, resulting in a layer shift. The good news is that the print stayed very firmly stuck to the bed.

I’ve reset, lowered my extrusion multiplier a smidge, switched to a more traditional support pattern, and am going for it again. Wish me luck!

The printer is a a Voron 2.4 running klipper with a chamber thermistor, controlled bed fans, and an exhaust fan so it will do a decent job regulating it’s temperature. The electronics are outside the chamber and there are acrylic panels under the blanket and hoodies. Should it come to it, klipper has thermal runaway protection. There’s also a smoke alarm right next to the printer. I suspect this will be a pretty uneventful print.

I let the printer heat soak for an hour and a half before giving it a go and barely cracked 60 °C, so all should be well. This is a Voron, so the electronics are out of the chamber, have a cooling fan, etc.

Other than looking somewhat janky, this isn’t that different than the insulated panels I’ll be swapping on to replace the current acrylic panels.

None of this stops the risk of fire.

Once a fire starts, the printer turning off won’t magically stop the fire from continuing to grow.

Printers can fail in all manner of ways.

Also, you should have a venting solution of printing ASA.

It’s pretty cheap to get a proper fire resistant heat cover for a printer.

Just get an emergency “space blanket”, they’re often only a couple bucks and quite good, but very fire resistant.